Texturing Matter: An Accessible Method of Creating Textures by Digital Subtractive Fabrication

In response to the growing interest in digital clay fabrication, this graduation thesis introduces TEXTURING MATTER, a simplified, accessible method that integrates traditional clay knowledge with digital manufacturing. Built on the multifunctional Zmorph CNC platform and custom Grasshopper software, the system bridges manual and digital practices by enabling a wide range of users—from traditional artisans to digital makers—to design and carve clay textures. It emphasizes the importance of understanding clay-specific knowledge, such as material properties and firing, which is often overlooked in existing research.

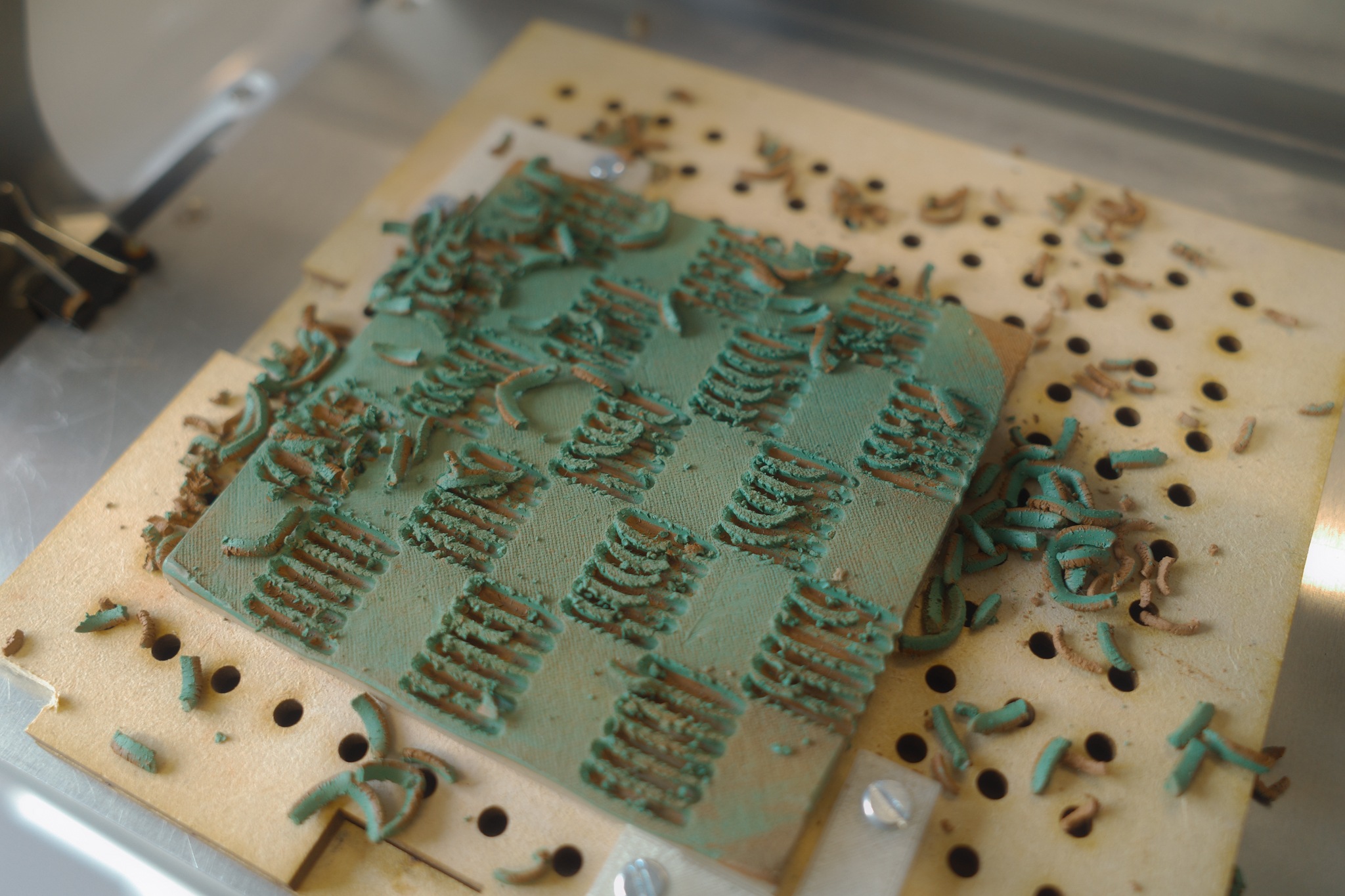

TEXTURING MATTER includes a hardware toolkit, parametric path-generation interface, and user guide. It focuses on three core variables: tools, materials, and machine paths. Users engage in iterative texture experimentation to build intuitive understanding and creative control. The method was further validated through an internship at Vertico, a concrete 3D printing firm, by adapting the system to larger-scale concrete printing and CNC milling. This demonstrated the method’s scalability and cross-material adaptability.

Ultimately, the project promotes digital craftsmanship, making decentralized digital making more inclusive and materially informed.

To facilitate a clearer understanding of the foundational knowledge behind the digital subtractive fabrication process, the workflow is simplified into the diagram above.

The research includes two parts:

(1) TEXTURING CLAY is the central focus of the research. It explores carving with a small-scale multi-functional CNC machine (Zmorph), using Grasshopper software I developed to carve clay along the design path.

(2) TEXTURING CONCRETE is the extension of TEXTURING CLAY. It investigates robotic arm milling as a method of renovation with VERTICO during my three-month internship.

The research includes two parts:

(1) TEXTURING CLAY is the central focus of the research. It explores carving with a small-scale multi-functional CNC machine (Zmorph), using Grasshopper software I developed to carve clay along the design path.

(2) TEXTURING CONCRETE is the extension of TEXTURING CLAY. It investigates robotic arm milling as a method of renovation with VERTICO during my three-month internship.

As someone attempting to learn from both traditional clay craftsmanship and digital fabrication, I have studied these seemingly different fields separately, yet gradually began to perceive their fundamental similarities—both embody complex and deeply embedded tacit knowledge, rely on the creator’s long-term hands-on engagement, and yet lack an integrated learning methodology.

I started to realize that “making fabrication more accessible and user-friendly” is the direction I want to pursue. To that end, I approach it from three perspectives:

(1) Organizing the processes I have learned into clear workflows, and conclude them in a clear booklet.

(2) Inspired by the Material Driven Design(MDD) approach, keeping a material diary to document my material experiments, identify key parameters in carving practices, and record reflections.

(3) Developing an intuitive Grasshopper-based design interface that enables users of different skill levels to explore carving possibilities simply by adjusting parameters.

I started to realize that “making fabrication more accessible and user-friendly” is the direction I want to pursue. To that end, I approach it from three perspectives:

(1) Organizing the processes I have learned into clear workflows, and conclude them in a clear booklet.

(2) Inspired by the Material Driven Design(MDD) approach, keeping a material diary to document my material experiments, identify key parameters in carving practices, and record reflections.

(3) Developing an intuitive Grasshopper-based design interface that enables users of different skill levels to explore carving possibilities simply by adjusting parameters.

This research adopts and slightly modifies the DIY Pen Toolhead originally designed by creator Marcin Traczyk in the Zmorph community, using its structure to mount self-made carving tools. Considering that the pairing of carving tools and carving path can produce multiple dynamics and significantly influence the final texture, I chose to focus on designing the machine’s movement rather than the textures themselves.

I developed a Grasshopper-based slicer specifically for carving clay slabs. With this design platform, users can create texture designs by following these steps:

(1) Basic Setting: input the clay slab dimensions and desired carving depth;

(2) select a carving tool;

(3) design the texture;

(4) preview the 2D and 3D texture patterns, as well as the combined effect of multiple tiles arranged together; finally, preview the tool’s carving process;

(5) export the final G-code for the machine to carve.

The Grasshopper-based interface allows users to explore variations of texture simply by dragging parameters, lowering the barrier to design while expanding the space for creative exploration.

I developed a Grasshopper-based slicer specifically for carving clay slabs. With this design platform, users can create texture designs by following these steps:

(1) Basic Setting: input the clay slab dimensions and desired carving depth;

(2) select a carving tool;

(3) design the texture;

(4) preview the 2D and 3D texture patterns, as well as the combined effect of multiple tiles arranged together; finally, preview the tool’s carving process;

(5) export the final G-code for the machine to carve.

The Grasshopper-based interface allows users to explore variations of texture simply by dragging parameters, lowering the barrier to design while expanding the space for creative exploration.

In the final part, the collaborative project with Vertico aimed to reproduce and restore heritage components through cement printing and carving techniques, while further developing Vertico’s digital milling aesthetics. We studied the surface textures of components dismantled during the restoration of a church, and selected semi-cylindrical drill bits suited to replicate the texture quality for carving execution.

Through the process of learning and experimenting together with Vertico, I recognized the potential of adapting the same Grasshopper-based software system from clay to cement. I also came to understand that the design path itself is only a small part of the process—the real key lies in mastering and understanding the characteristics of different materials and machines to ensure that the method can be successfully implemented.

Through the process of learning and experimenting together with Vertico, I recognized the potential of adapting the same Grasshopper-based software system from clay to cement. I also came to understand that the design path itself is only a small part of the process—the real key lies in mastering and understanding the characteristics of different materials and machines to ensure that the method can be successfully implemented.

The developing TEXTURING MATTER project is gradually update to Instagram page @observ.ology and the Youtube channel.

Year: 2025

Designer: Yaya Huang

Coach: Bahareh Barati @Eindhoven University of Technology @Sensory Matters Squad

Special Thanks:

Vertico

D.search for general lab and tools supports.

TU/e Innovation space wood workshop for letting me fire clay piece almost everyday.

釉彩家 蔡佳霖 Jia Lin Tsai for supporting all the clay/craft relevant professional insights.

Bahareh Barati as my mentor who guide me all the way through my masters.